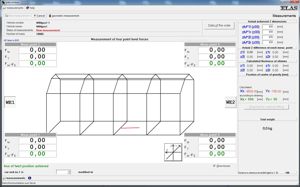

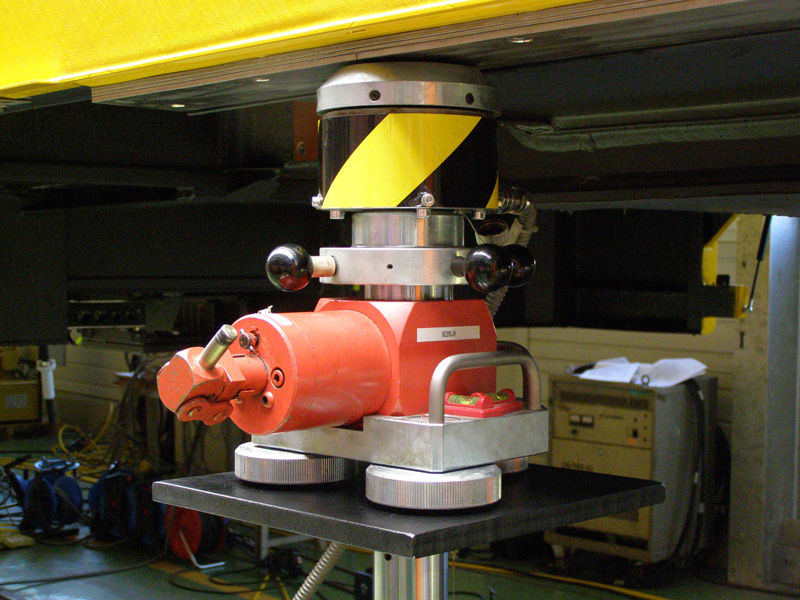

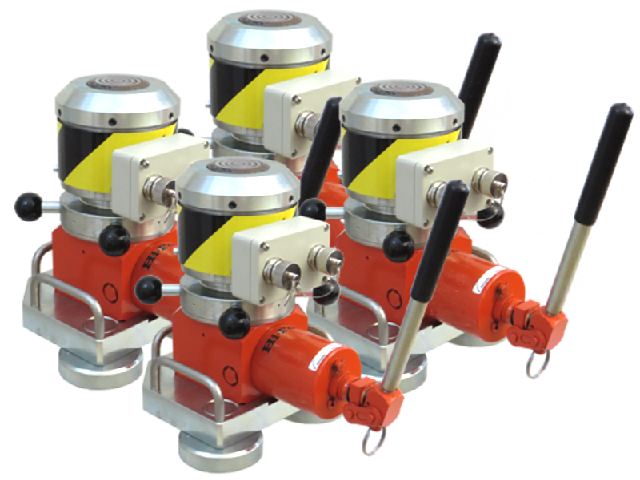

The ELAS-m corner force measuring system is a low-cost alternative to the automatic ELAS-a system. This transportable four-point measuring system can easily be integrated in jack systems and has a precision lift facility.

The ELAS-m mobile corner force measuring unit is a very flexible high-precision system designed to calculate and set positions and reference positions of low torsional stress on coach bodies and to calculate the centre of gravity, including on locomotives. It is used in bodywork and final assembly processes, retrofits and repairs and is also used to analyse the condition of vehicles which have been involved in accidents. The ELAS-m corner load measuring system conforms to the requirements set out in DIN 25043 (reference force measurements). The system is also used to calculate the shim thicknesses required for the undercarriage which will subsequently be used and the gross weight.

ELAS-m features

ELAS-m features